Bedside Table

September 2025

Duration: 3 weeks

Project Description:

A low-parameter furniture project that began with form and joinery research. The final product could not include cabinetry, drawers, or other closed compartments. Joinery was to include floating tenons and/or domino joints. Hardware was discouraged.

Total pieces: 434

Wood species: Walnut & cherry

Power tools used: 12

IDEATION

CONSTRUCTION

Table Assembly

Left: A creative setup to cut perfect squares out of the corners of the shelf. These cut-outs would be for the table legs to rest inside of.

FINALS

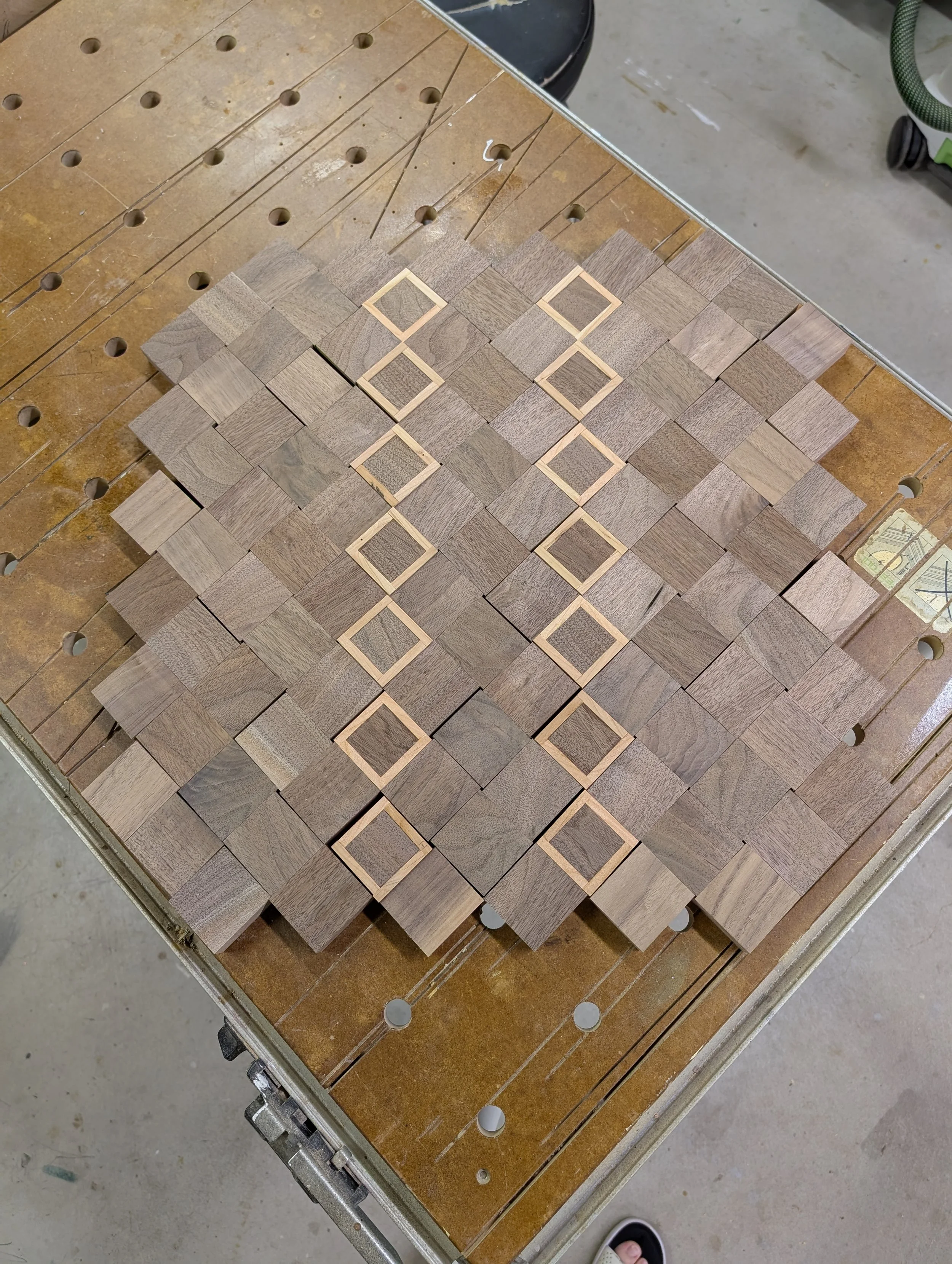

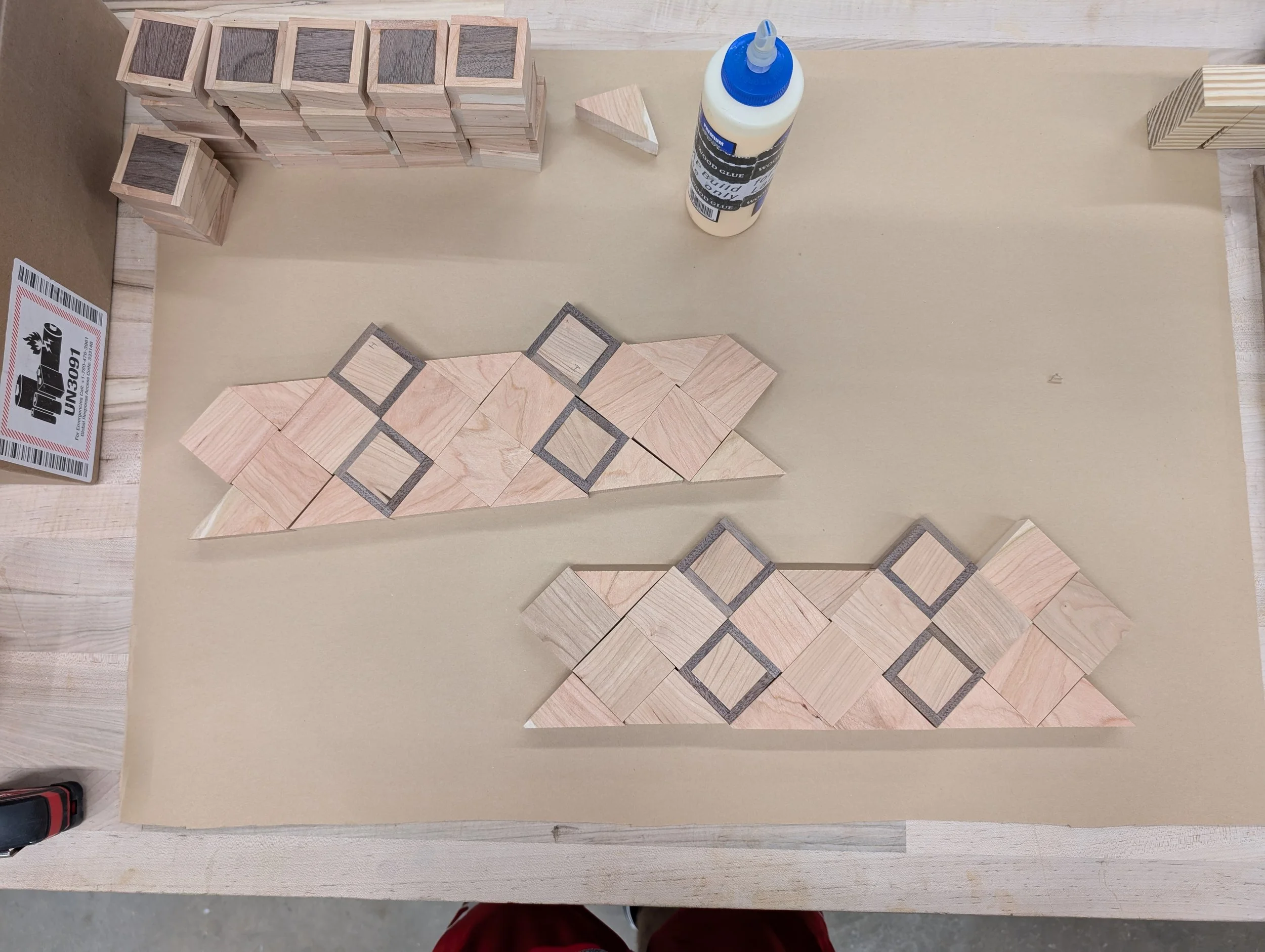

Above: Glue-up of inlayed squares for the table top and shelf

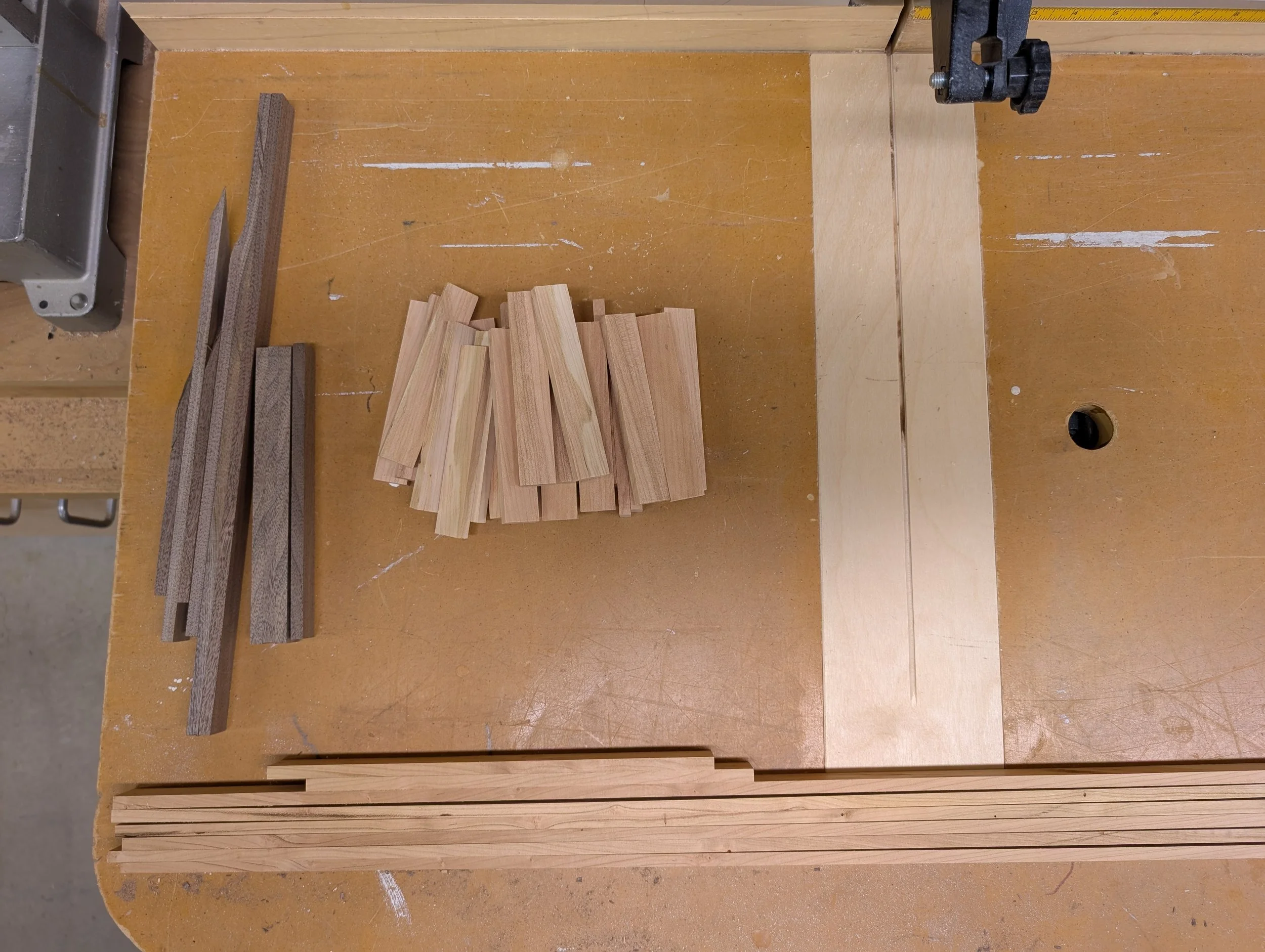

Right: Finalizing dimensions of inlayed squares by trimming edges

Left: Glue-up of legs via lamination

Right: Smoothing surfaces via drum sander

Left: Using dominoes and tenons as primary joinery method

Right: Assembly of the table, beginning with the aprons and legs. The aprons were attached with dominoes, and the legs with tenons. The table top and shelf were secured with pocket screws.

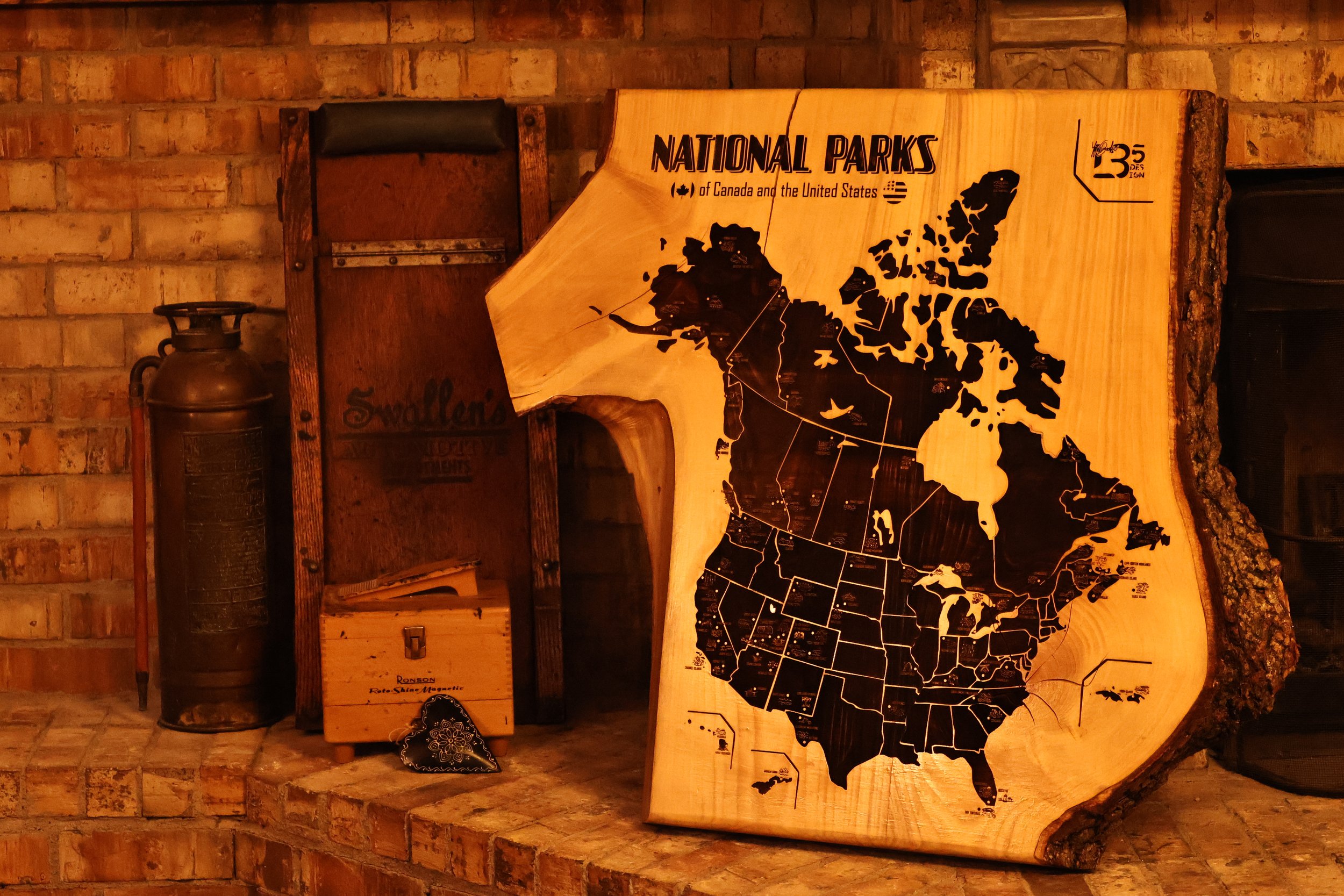

After a coat of Danish oil.

There was a lot of math and measurement work to be done before finally beginning the cutting process. After determining the correct widths and lengths needed, I got to work with the planer, jointer, and table saw.

Assembly of Table Top & Shelf

Rough layouts of the table top, shelf, and aprons, followed by the first glue-ups of strips of squares.

The most time-consuming part of the construction process was easily creating the squares that make up the table top and shelf, particularly the ones with outlines of the opposite wood type (thin pieces below).

After flattening the sides of each strip with the table saw, they were able to be glued together without gaps. I then carefully cut the four pieces to the correct shapes and sizes on the table saw.

The final step of construction was adding thin trim pieces to the intersection points of the aprons and legs, creating a smooth and refined transition between pieces.