Lego Table

May-December 2025

Duration: 7 months

Project Description:

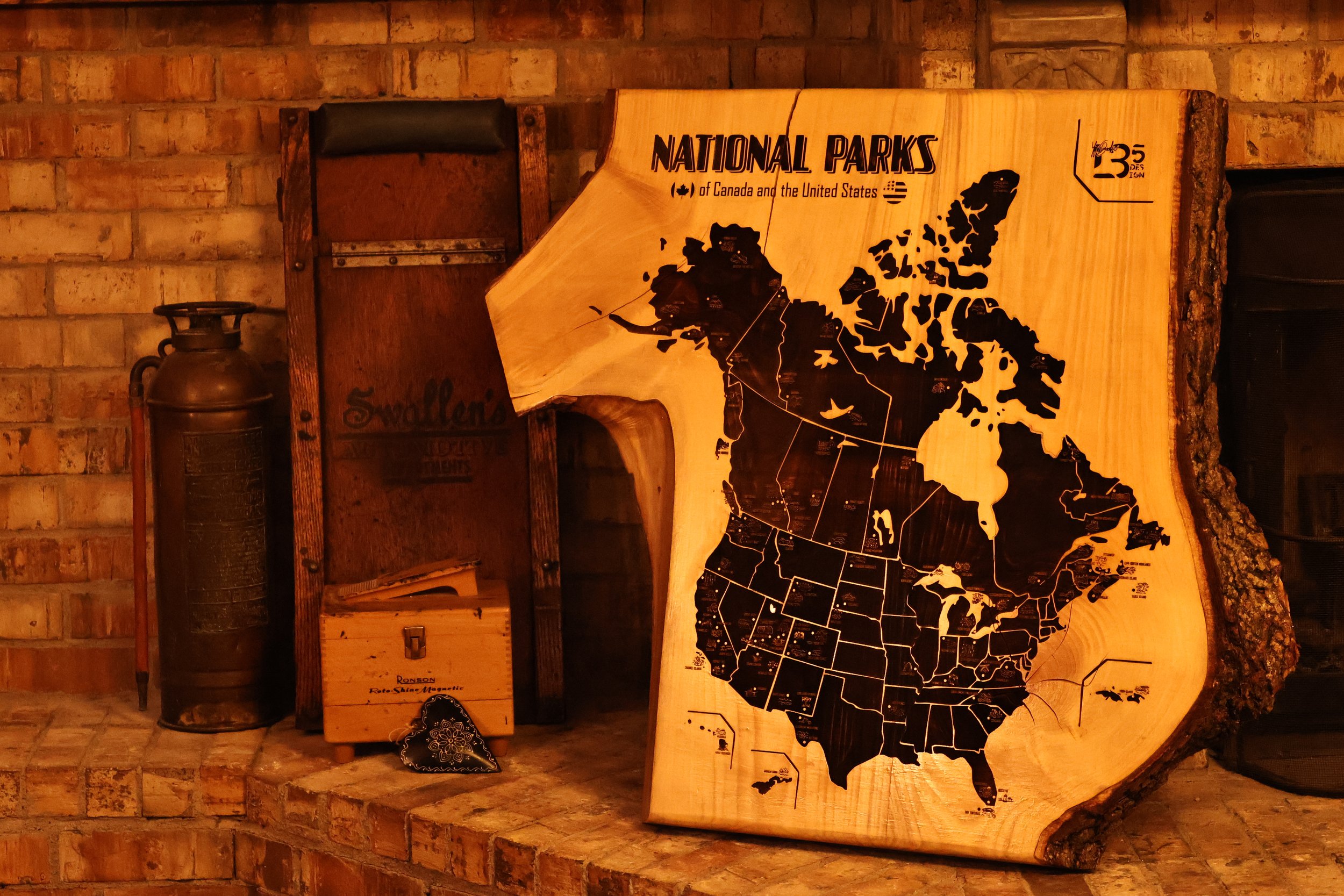

What began as a summer project turned into a long journey with many learning opportunities. This table required a combination of skills, including fine woodworking, pattern making, and knowledge of epoxy resin. The final result highlights all of these areas of expertise as a stunning and functional coffee table.

Project Goals:

I had an ambitious vision heading into summer break for this table. My original goal was just to get rid of some of my old Legos that had been sitting around for so long. But once I got the project rolling, I was determined to make this a highlight of my portfolio.

Legos used: ~6,000

Epoxy poured: 3.5 gallons

Weight: 160 lbs

Wood species: White oak & cedar

IDEATION

The design for this table came to me without much thought, along with the idea itself, leading to a short ideation phase that was overwhelmingly spent in Fusion.

I largely worked out dimensions and preliminary materiality while creating this base model.

Table Top

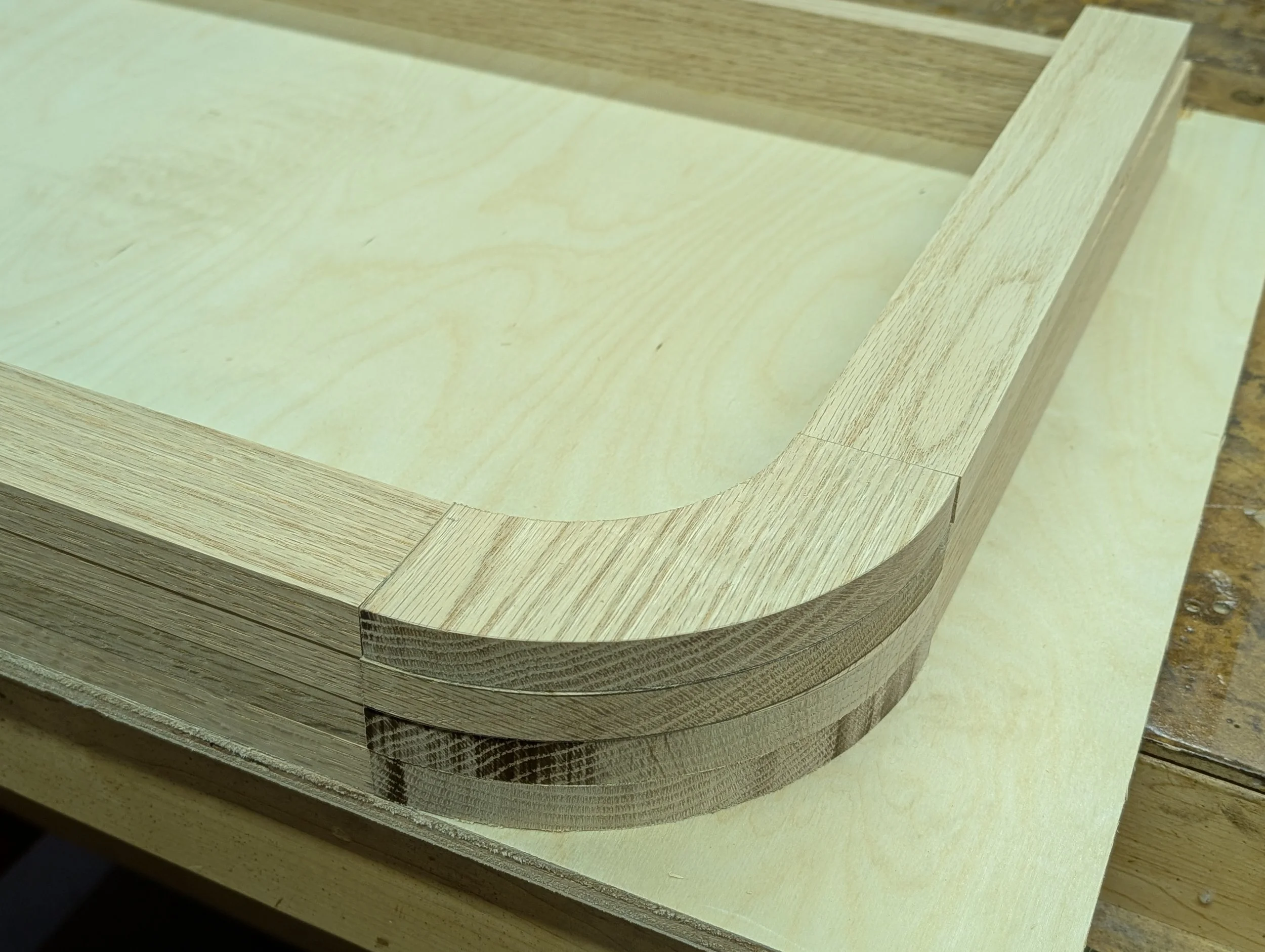

The frame was made using two primary forms: beams and arcs (to act as corners). Both would stack to create the depth of the table. This was the best way for me to create rounded corners, as opposed to bending wood.

CONSTRUCTION

Process

Both the corners and the sides were composed of three 1-inch-thick pieces and a ~2-inch-thick piece on top that hung over toward the inside of the table top.

Gluing and clamping were simple processes; however, I had to get creative when it came to sanding the corners. Due to the top layer hanging over the rest of the pieces, it was difficult to sand the inner face. I rigged up a belt sander with a handscrew clamp to allow the thicker edge to hang over the side of the sander.

Finally, once the frame was sanded and lined up, I cut the plywood piece that would eventually hold the Lego design.

Planed and sanded down each leg smooth

The corners were a bit more complex, however, I used the same strategy. Holding the flat edge against the table saw rail, I ran each piece through a few times at the same depth as the legs.

Table Top Assembly

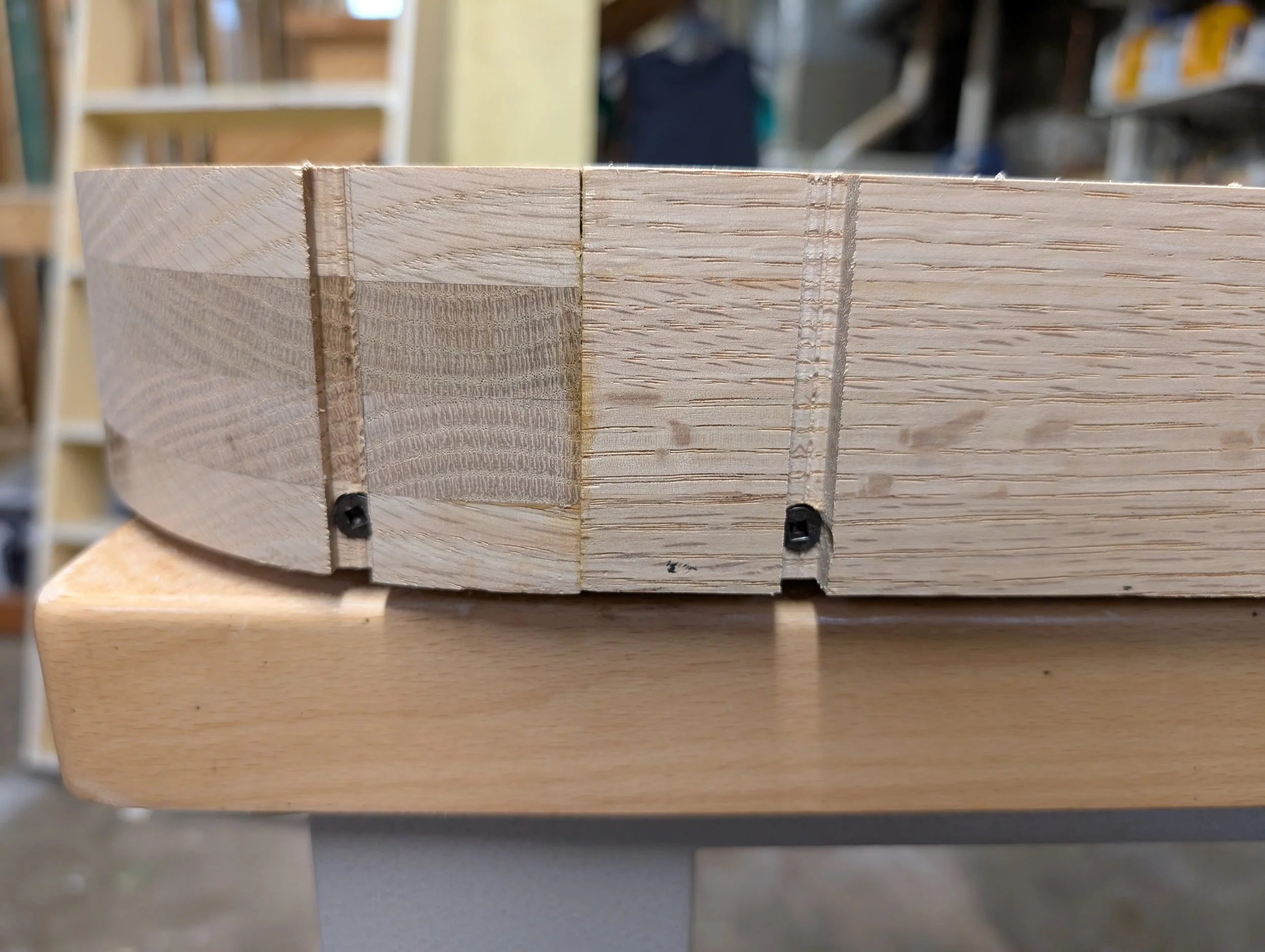

The frame was assembled with screws and glue.

The plywood was attached with screws placed inside the Lego grooves (in order to hide them) and braces on the underside of the table.

Once the strips were glued, I sanded the Legos to be even with the wood surface.

Embedding Legos

Sanded and glued to each leg

Used scroll saw to cut out Lego connectors

The final modification that needed to be made to the wood before assembly was the addition of pocket screw holes.

Early testing of finishes (I planned to stain only the legs and add a coat of warmly-tinted polyurethane to everything).

Due to limited amounts of some colors, I had to cut apart larger pieces that could act as 1x1 bricks. This meant that there could be one torn-up side on each piece that would simply be facing the back of the grooves. This created some very colorful dust on the scroll saw table.

FINISHING

I chose a golden oak stain for the legs due to its ability to cover up the red tint from the cedar, and because it complemented the lighter, yet still warmly-tinted, white oak.

The legs were sanded to a very fine grit in order to remove scratches from the surface of the Legos. After a quick dust-off, they were ready to be attached to the table top.

I cut off the tops that stuck out and filled them w/ epoxy.

PLAYING WITH LEGOS

FINALS

Similarly, I sanded the Legos flat to the surface, cut off the protruding tops, and filled the holes with epoxy.

The most difficult problem to solve for the table top was the holes that were created when sanding the Lego strips on the corners. Due to the roundness of those pieces, the grooves were shallower on one side, meaning more material had to be removed to create a smooth transition. I chose to fill those holes with epoxy as well, but had to do so by quickly trapping the epoxy inside with tape until it dried to avoid spillage. I sanded the epoxy smooth once dry.

After staining the legs, I attached them to the table top via wood glue and large countersunk screws from the top.

Finished frame after two coats of a warmly-tinted oil-based polyurethane.

After sealing the inside and the outside of the table top with a silicone caulk, I poured deep-pour epoxy over the entire Lego surface.

Early rendering w/ placeholder surface design

I did not have a solidified design chosen going into the Lego building process; however, I was inspired by artist Katherine Duclos, who has created some amazing works using Legos. Her designs often have a unique blend of chaos and harmony, and I wanted to incorporate some aspect of that into my design. However, I came into this with the goal of using up as many old Legos as possible, so I wanted to use every color I had, which limited the amount of harmony I could create. I began experimenting with patterns and designs, taking inspiration from natural wonders, movies, games, color schemes, and anything that popped into my head. This unique combination of designs is what makes this table special and creates its story.

POURING EPOXY

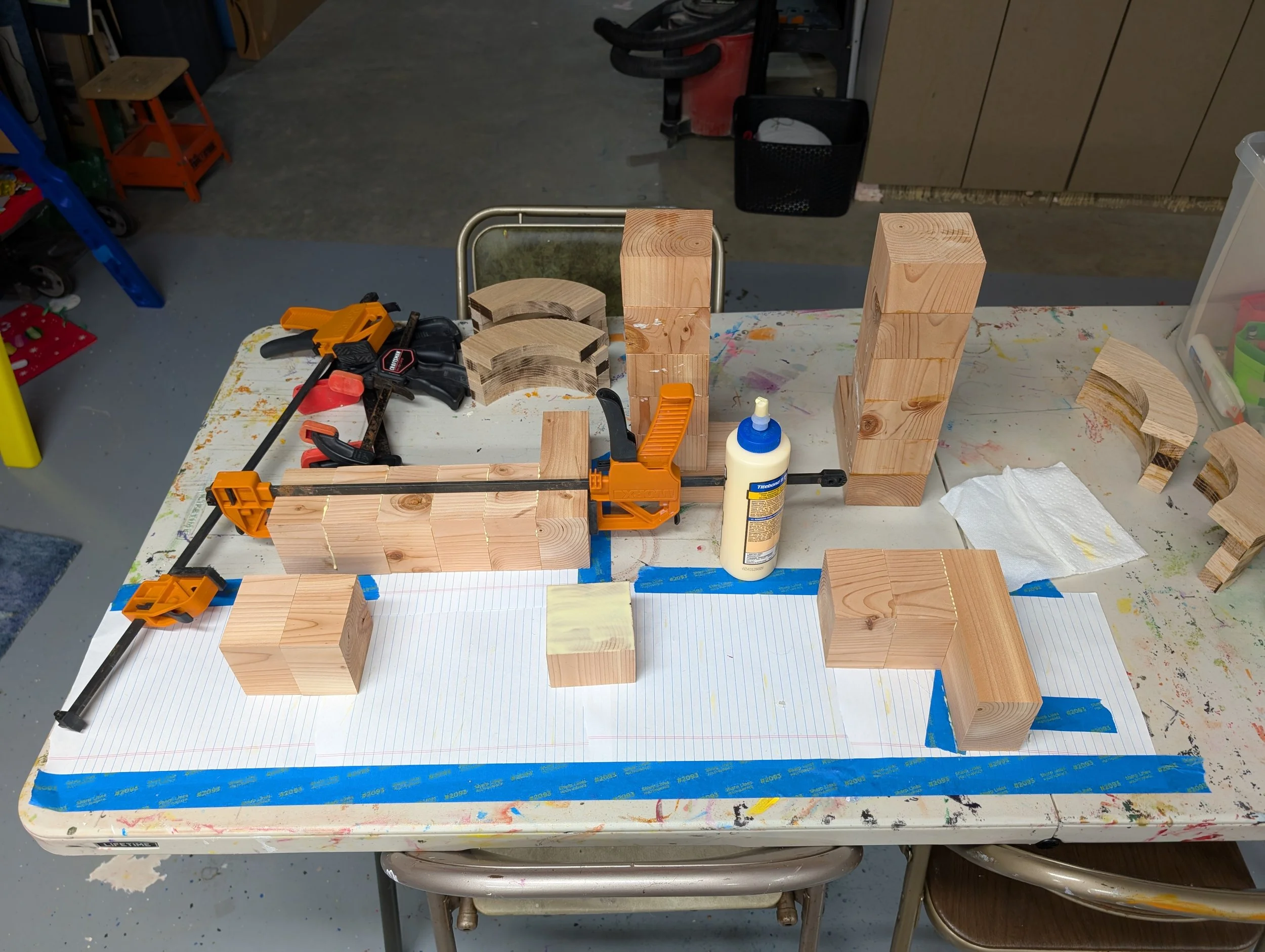

Wood choices: White oak for the table top and cedar for the legs.

Reasoning: My decision-making regarding wood species centered around color and price. I chose a lightly colored wood for the table top because I did not want the wood to draw attention away from the Lego design that would be covering the surface. Legos are generally bright and vibrant, and a darker wood (such as walnut) would create extreme contrast. White oak also offered a low price tag, as I was working on a budget. As for the legs, cedar was the obvious choice because it is one of the few woods used to make 4x4 posts. Generally used for fencing and decking, I chose to utilize them because of their square profile, which was an excellent fit for creating blown-up Lego bricks.

Legs

Cut down 4x4 post

Glued up five squares w/ each rectangle

Final Touches & Assembly

I would eventually embed Legos into the legs and table top frame, meaning I needed to cut the grooves for them to rest in before assembly. The legs were rather easy, as I just sent them across the table saw a few times at the necessary depth.

The entire table top was sanded, mainly to smooth out joints

I gathered every 1x1 Lego brick I had and sorted by color to determine which ones I could use in the pattern.

After creating a pattern that I was happy with, I began laying the Lego strips in place.

The process was similar for the table top when it came to placing the Legos. Tape was necessary to prevent the strips from slipping down when the glue was drying.